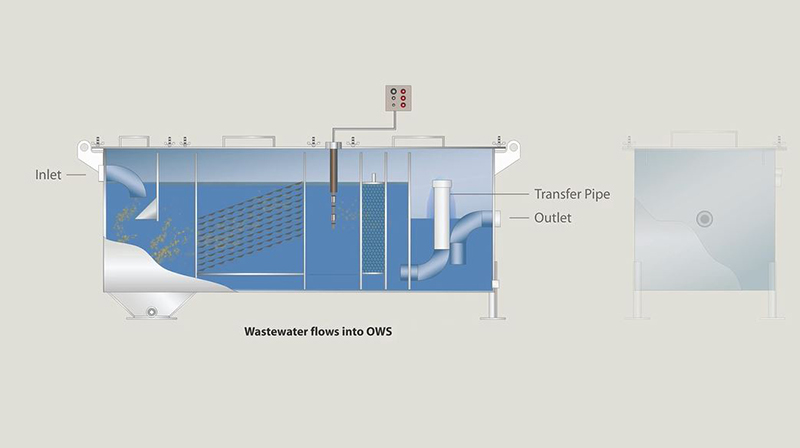

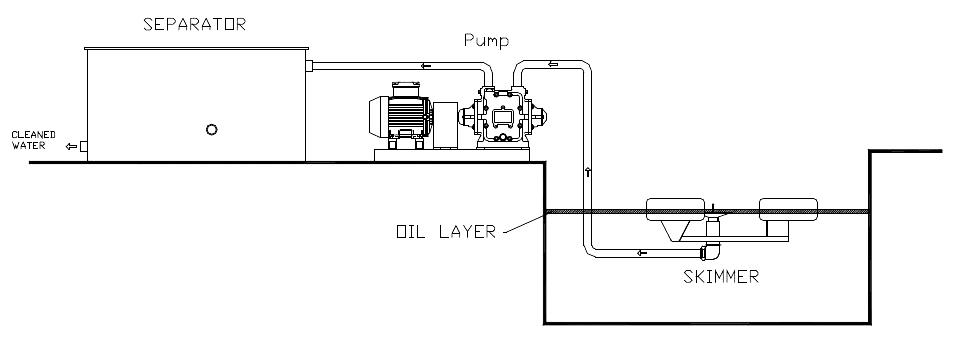

An api oil water separator is a device designed to separate gross amounts of oil and suspended solids from the wastewater effluents of oil refineries petrochemical plants chemical plants natural gas processing plants and other industrial oily water sources.

Api oil water separator sizing.

The api type design relies on a large water volume.

Must be 3fpm note.

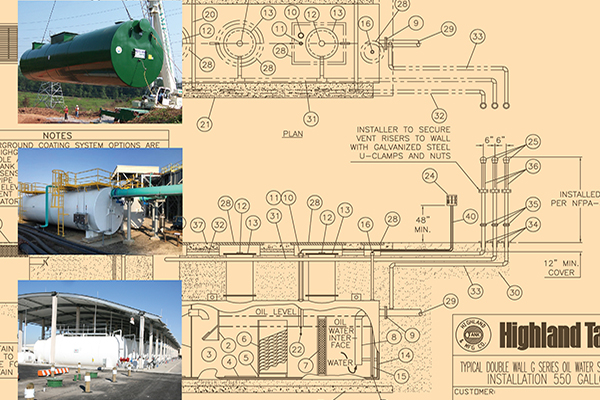

The information contained herein is the opinion of highland tank.

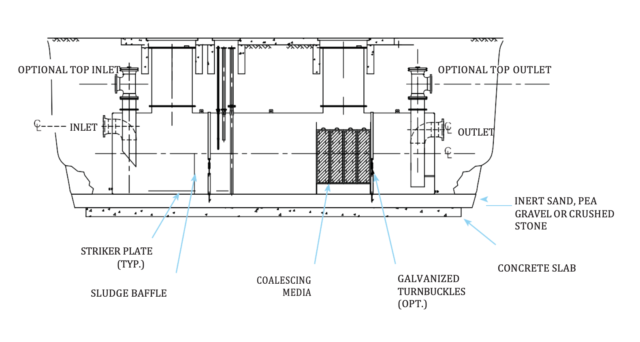

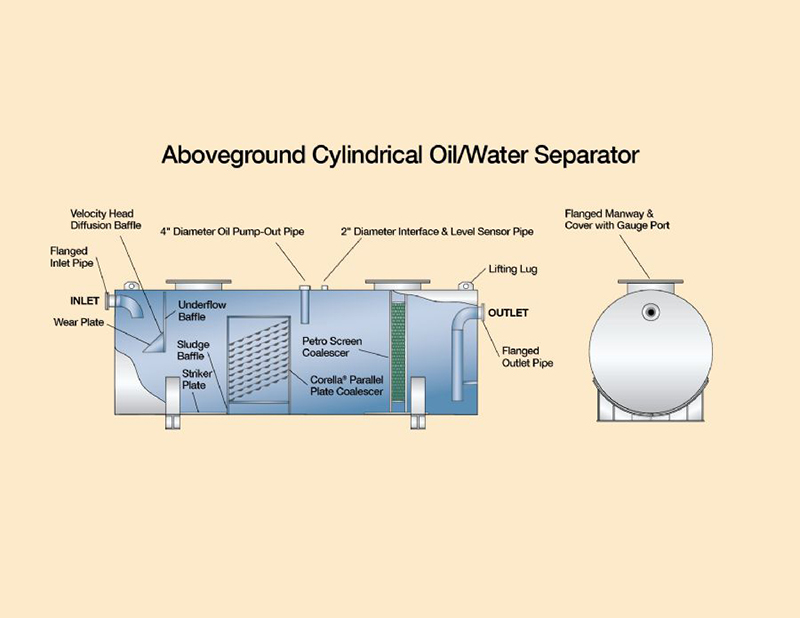

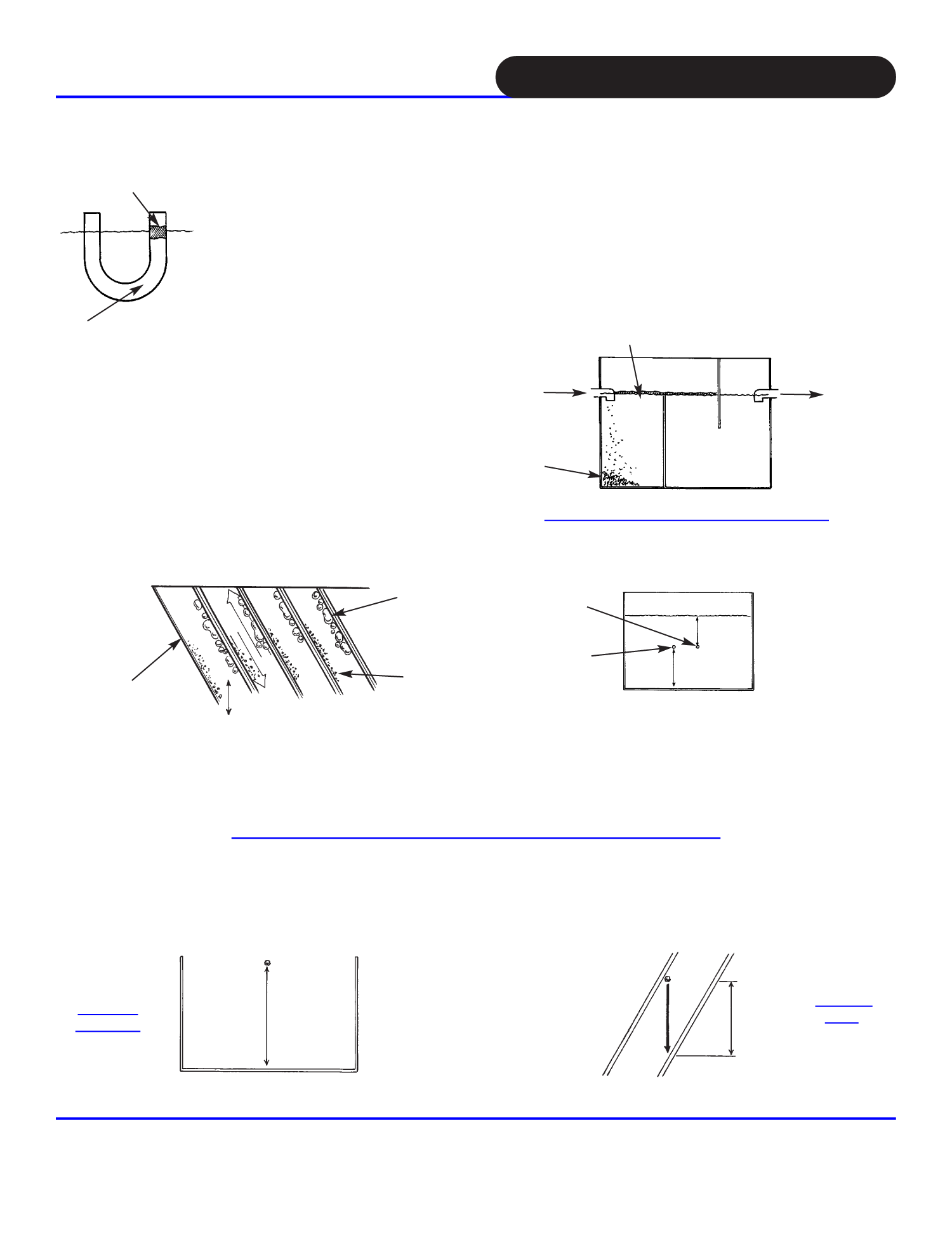

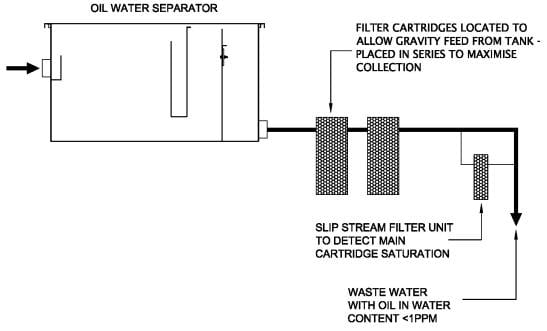

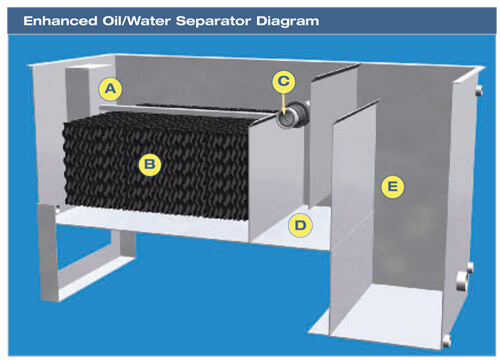

Oil water separators are typically the american petroleum institute api also called baffle type american petroleum institute 1990 or the coalescing plate cp type using a gravity mechanism for separation.

Oil droplets from 20 to 150 microns in diameter.

8 16 2016 5 28 46 pm.

The name is derived from the fact that such separators are designed according to standards published by the american petroleum.

Oil droplets 150 microns in diameter and larger.

Oil water separator sizing calculation.

Individual projects must be evaluated to determine the appropriate size and configuration for that site.

Below is a link to an api oil water separator sizing spreadsheet developed by hydro flo technologies.

This design also known as an api separator generally provides a discharge oil concentration of 100 ppm based on a 150 micron droplet size.

See figure 5 33 and figure 5 34.

This guide is intended to assist knowledgeable personnel with sizing a highland tank oil water separator.

The api type design relies on a large water volume.

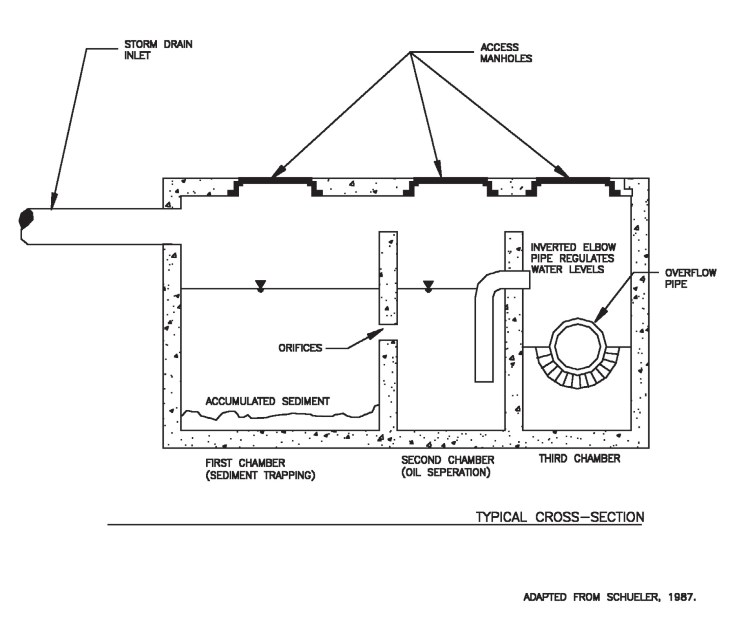

Api tanks were originally designed by the american petroleum institute api for use in refinery applications but modifications of the design can be used for stormwater treatment.

This correlates to a tank size that can be 5 times the size of an equally sized coalescing separator.

By inputting the major design criteria you can solve for the separation chambers width to length to depth ratios.

Oil water separator oil droplet sizes definitions and meanings.

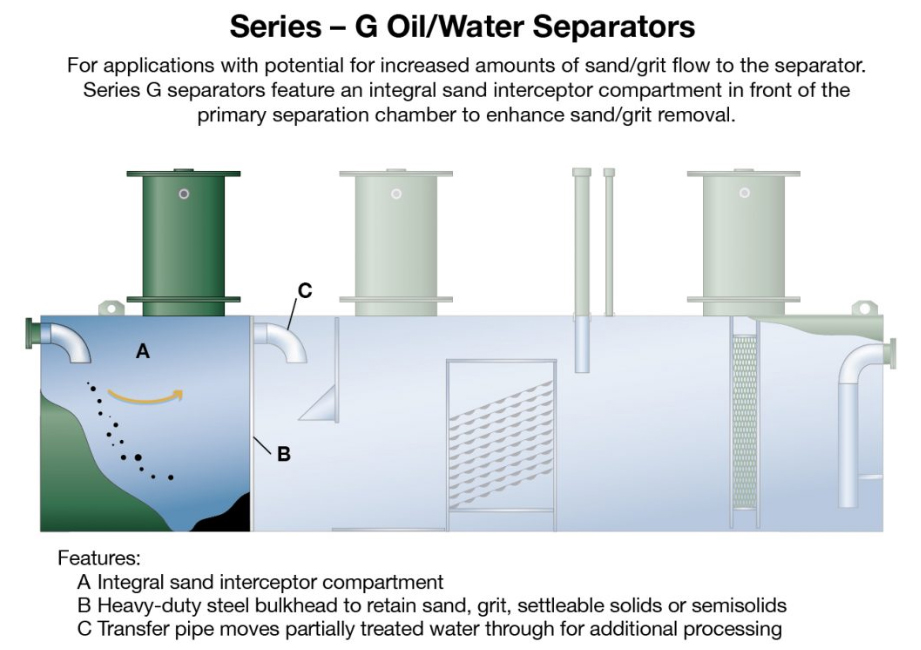

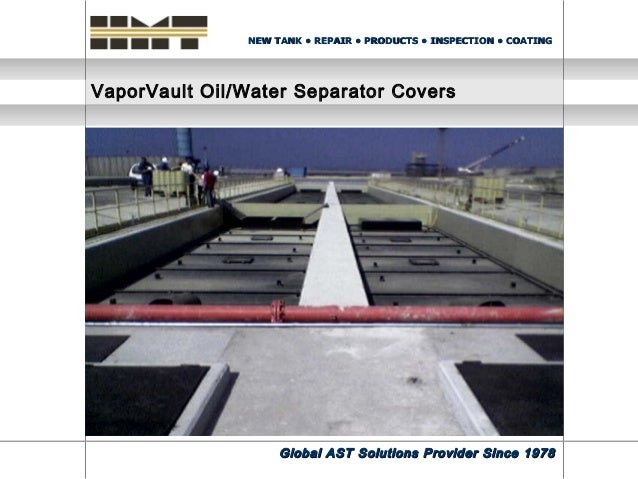

33 1 2 types of separator api tanks see figure 33 1 and plate separators are the more efficient oil separators.

Below is a sample shot of the spreadsheet.

This calculation is based on the methods proposed.

0 9860 density of the water s g g cm3 0 0052 viscosity in poise 1 2568 rise rate of oil droplet gpm ft2 calculated 159 13 horizontal surface area area ft2 of the separator needed to achieve desired oil removal performance 0 89 cross sectional velocity ft min.

Following are the definitions and categories of different oil droplet sizes as defined by the american petroleum institute in the mid 1970 s.

This correlates to a tank size that can be 5 times the size of an equally sized coalescing separator.

Sizing ows calculation per api 421 xls author.

Oil water separators typically consist of three bays.

The spreadsheet operates on microsoft excel 2003 or later.

.png)